Iyini imishini ye-CNC ye-axis emihlanu?

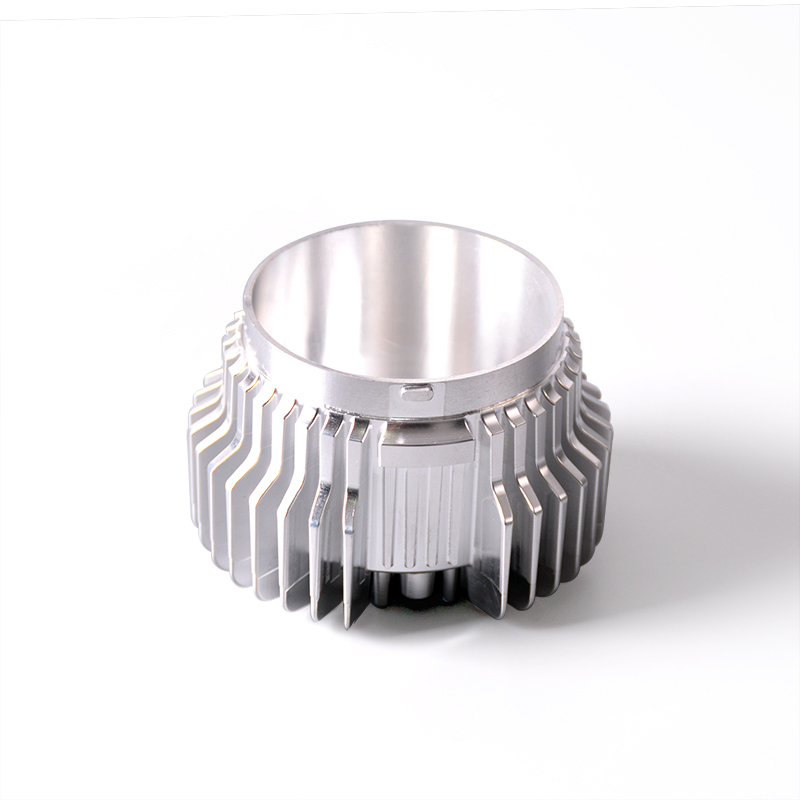

Isebenzisa ubuchwepheshe obuncishisiwe bokucubungula izinto ukuze inikeze amathuba angenamkhawulo wokudala ingxenye. I-workpiece isikwa ngendlela oyifunayo nosayizi kusetshenziswa ithuluzi lokusika elisebenza ezimbazweni ezinhlanu.

5-axis machining kunikeza ukunemba okwengeziwe nokunemba, ukusebenza kahle nokuthembeka. Ukwanda kwenani lezimbazo kunikeza umshini wokugaya onama-axis amahlanu amandla okuba ngcono kunemikhiqizo efanayo. Ngaphezu kwalokho, le nqubo ivumela ukuzenzekelayo nokuphatha okugcwele kusetshenziswa i-computer digital control (CNC).

Le nqubo ibandakanya ithuluzi lokusika elihamba ngezimbazo ezinhlanu ngesikhathi esisodwa. Imishini ye-CNC ye-5-eksisi ihlinzeka ngezimbazo ezintathu ezilandelanayo kanye nezimbazo ezimbili ezijikelezayo ezisebenza kanyekanye ukuze zibone izingxenye eziyinkimbinkimbi. Lokhu kuvame ukwandisa ukutsheka kwetafula noma ithuluzi, okwandisa ukujikeleza nokunyakaza.

Umehluko phakathi kwezimbazo ezinhlanu nezimbazo ezintathu

Ukucubungula ithuluzi lomshini we-axis amathathu, ekucubunguleni ukunemba kwe-3D workpiece akuphakeme, njenge-impeller, nakuba ingacutshungulwa, kodwa ukunemba kuphansi, futhi ithuluzi alikho perpendicular ekucubunguleni kwendawo yokucubungula, ithuluzi alikho. umkhiqizo omkhulu kunayo yonke; Kukhona nezinye izinto zokusebenza ezingakwazi ukusetshenzwa ngomshini wamasonto amathathu.

Ukucubungula ithuluzi lomshini we-axis emihlanu, ukuxhumana kwe-axis emihlanu akukona okugxilwe kukho, kugxilwe yi-RTCP noma i-TCP, okungukuthi, isilawuli sephoyinti lesikhungo samathuluzi, ngokulungiswa, ungaqinisekisa ukuthi umshini, ithuluzi lihambisana nendawo yomshini. , ukuqinisekisa ukuthi ithuluzi lisesimeni esiphezulu sokuphuma, kodwa futhi nokuqinisekisa ukunemba kokucubungula.

Kungani kufanele ukhethe izinsiza zethu zemishini ye-5-axis?

1. Nciphisa inani le-clamping. Ngenxa yokuba khona kwezimbazo ezimbili ezijikelezayo zethuluzi lomshini wama-eksisi amahlanu, ithuluzi lingasondela endaweni yokusebenza ukusuka kunoma iyiphi indlela, futhi zonke izindawo ngaphandle kwendawo ekhwezayo zingenziwa ngomshini ngesikhathi esisodwa. "Ukunciphisa inani lokuphoqa" kungashiwo ukuthi kubulala izinyoni ezimbili ngetshe elilodwa ngokuphishekela ukusebenza kahle nokunemba okuphezulu. Ngakolunye uhlangothi, ukunciphisa inani lokubopha kungasindisa isikhathi, kunciphise ukushuba kwabasebenzi, futhi kuthuthukise ukusebenza kahle kokucubungula; Ngakolunye uhlangothi, amaphutha angase alethwe umhlangano kanye namaphutha okubamba angancishiswa ngangokunokwenzeka ukuze kuqinisekiswe ukunemba kwemishini.

2. Gcina isimo esihle kakhulu sokusika sethuluzi futhi uthuthukise izimo zokusika. Ngenxa yokusetshenziswa kwamathuluzi omshini we-axis emihlanu, ithuluzi lingasondela kunoma iyiphi isiqondiso kuya ku-workpiece, ukuze ithuluzi lisetshenziswe ku-Angle efanelekile kakhulu ukusika umsebenzi. Ingase futhi ithuthukise ukusebenza kahle kokucubungula kanye nekhwalithi yokucubungula.

3. Gwema ngokuphumelelayo ukuphazamiseka. Futhi ngenxa yokuba khona kwezimbazo ezimbili ezijikelezayo zethuluzi lomshini we-axis emihlanu, ithuluzi lingasondela ku-workpiece kunoma iyiphi indlela, okwenza indlela yomshini iguquguquke. Ingakwazi ukugwema ngempumelelo izinkinga zokuphazanyiswa ngesikhathi sokucubungula.

4. Fushanisa umjikelezo wokuthuthukiswa. Lona futhi umphumela wemvelo wokuthuthukisa ikhwalithi nokusebenza kahle.