Chii chinonzi shanu-axis CNC machining?

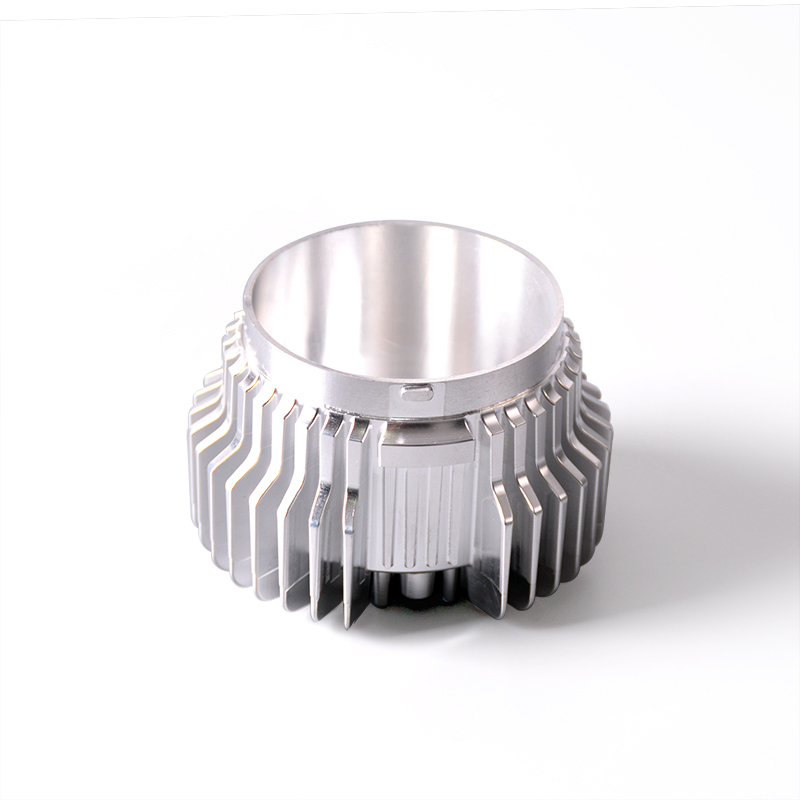

Inoshandisa yakaderedzwa tekinoroji yekugadzirisa tekinoroji kuti ipe unlimited mikana yechikamu chekugadzira. Iyo workpiece inochekwa kune yaidiwa chimiro uye saizi uchishandisa chishandiso chekucheka chinoshanda pamasanhu mashanu.

5-axis machining inopa kuwedzera kurongeka uye kurongeka, kunyatsoita uye kuvimbika. Kuwedzera kwehuwandu hwematemo kunopawo mashanu-axis milling muchina kugona kuve nani pane zvigadzirwa zvakafanana. Uye zvakare, maitiro anobvumira kuzere otomatiki uye manejimendi uchishandisa komputa dhijitari control (CNC).

Kuita uku kunosanganisira mudziyo wekucheka unofamba pamatemo mashanu panguva imwe chete. 5-axis CNC michina inopa matatu mutsara matemo uye maviri anotenderera matemo anoshanda panguva imwe chete kuona zvikamu zvakaoma. Izvi zvinowanzowedzera kutenderera kwetafura kana chishandiso, izvo zvinowedzera kutenderera uye kufamba.

Musiyano uripo pakati pemasanhu mashanu nemasanhu matatu

Matatu-axis muchina chishandiso kugadzirisa, mukugadzirisa kwe 3D workpiece kurongeka hakuna kukwirira, senge impeller, kunyangwe inogona kugadzirwa, asi iko kurongeka kwakadzikira, uye chishandiso hachina perpendicular pakugadziriswa kwepasi, chishandiso hachina. iyo yakakura kubuda; Kune zvakare mamwe maworkpiece asingagone kugadziriswa nemuchina wemavhiki matatu.

Mashanu-axis muchina chishandiso kugadzirisa, shanu-axis yekubatanidza haisi iyo yekutarisa, yakatarisana ndeye RTCP kana TCP, kureva, chishandiso chepakati point control, kuburikidza nekugadzirisa, unogona kuve nechokwadi chekuti machining, chishandiso chiri perpendicular kune machining nzvimbo. , kuve nechokwadi chekuti chishandiso chiri mune yakanyanya kuburitsa mamiriro, asiwo kuve nechokwadi chechokwadi chekugadzirisa.

Sei tichisarudza yedu 5-axis machining masevhisi?

1. Deredza nhamba ye clamping. Nekuda kwekuvapo kwematemo maviri anotenderera echishanu-axis muchina chishandiso, chishandiso chinogona kuswedera kune workpiece kubva chero nzira, uye ese maficha kunze kwekukwira kumusoro anogona kugadzirwa panguva imwe chete. "Kuderedza nhamba ye clamping" inogona kunzi inouraya shiri mbiri nedombo rimwe rekutsvaga kushanda kwakanaka uye kwepamusoro-kwakarurama machining. Kune rimwe divi, kuderedza kuwanda kwekurovera kunogona kuchengetedza nguva, kuderedza kuwanda kwevashandi, uye kugadzirisa mashandiro ekugadzirisa; Kune rumwe rutivi, zvikanganiso zvinogona kuunzwa neungano uye zvikanganiso zveclamping zvinogona kuderedzwa zvakanyanya sezvinobvira kuti ive nechokwadi chekugadzira machining.

2. Chengetedza yakanakisa yekucheka mamiriro echishandiso uye kugadzirisa mamiriro ekucheka. Nekuda kwekushandiswa kwezvishanu-axis muchina zvishandiso, chishandiso chinogona kuswededzwa kubva kune chero nzira kuenda kune workpiece, kuitira kuti chishandiso chigone kushandiswa paAngle yakakodzera kwazvo kutema workpiece. Inogonawo kuvandudza kushanda kwekugadzirisa uye kugadzirisa hutano.

3. Dzivirira zvinobudirira kupindira. Zvakare nekuda kwekuvapo kwematemo maviri anotenderera echishanu-axis muchina chishandiso, chishandiso chinogona kusvika kune workpiece kubva kune chero nzira, ichiita kuti machining nzira ichinjike. Inogona kunyatso kudzivirira matambudziko ekupindira panguva yekugadzirisa.

4. Kupfupisa kutenderera kwebudiriro. Uyu ndiwowo maitiro echisikigo ekuvandudza kunaka uye kushanda zvakanaka.