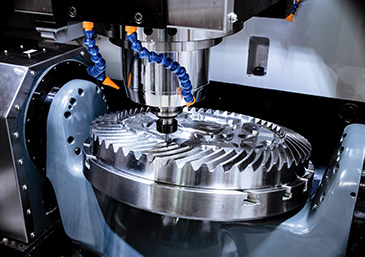

10 CNC gwaninta taƙaitaccen bayani, menene CNC machining?

CNC machining, wanda kuma aka sani da CNC machining, yana nufin amfani da kayan aikin sarrafa kwamfuta don yin mashin daidaici. Wannan hanya ta shahara a masana'antu daban-daban saboda fa'idodinta da yawa kamar ingantaccen ingancin sarrafawa, daidaitaccen daidaito, da ikon sarrafa sifofi masu rikitarwa. Duk da haka, dole ne a yi la'akari da dalilai na ɗan adam da kwarewa a lokacin aikin injiniya na ainihi kamar yadda zasu iya samun tasiri mai mahimmanci akan ingancin ƙarshe.

Don magance wannan matsalar, injinan CNC wanda ke da gogewar shekaru goma ya raba darussa masu mahimmanci guda goma sha biyu don ingantaccen injin CNC. Wadannan darussan da aka koya zasu iya taimakawa wajen inganta tsarin gaba ɗaya da samun sakamako mai kyau.

Darasi na farko yana mai da hankali kan rarraba ayyukan injinan CNC. Akwai hanyoyi daban-daban don yadda ya kamata a rarraba waɗannan hanyoyin. Ɗaya daga cikin irin wannan hanya ita ce tsarin tsarin kayan aiki, wanda ke rarraba matakai bisa ga kayan aikin da aka yi amfani da su. Ta amfani da kayan aiki iri ɗaya don cikakkun sassa, ana guje wa canje-canjen kayan aikin da ba dole ba, rage lokacin aiki da kurakurai na matsayi.

Wata hanyar da aka tattauna ita ce hanyar bibiyar sashin injina. Wannan hanya ta raba sassan da aka kera zuwa sassa daban-daban bisa ga tsarin tsarin su kamar siffar ciki, siffar waje, lanƙwasa ko jirgin sama. Ana bada shawara don aiwatar da shimfidar shimfidar wuri da wuri na farko, sannan aiwatar da rami. Hakazalika, ya kamata a fara aiwatar da siffofi masu sauƙi na geometric, sa'an nan kuma a fara sarrafa siffofi masu rikitarwa. ɓangarorin da ke da ƙananan buƙatun daidaito yakamata a fara sarrafa su, sannan a sarrafa sassan da mafi girman buƙatun daidaito.

Darasi na uku ya gabatar da manyan hanyoyin rarrabuwar kawuna na injinan CNC. Wannan hanya tana da amfani musamman ga ɓangarorin da ke da saurin nakasu a lokacin aikin mashin ɗin. Domin gyara duk wani nakasawa, ya zama dole a raba mashin ɗin zuwa matakan roughing da ƙarewa. Wannan yana tabbatar da cewa an inganta ingancin sarrafawa kuma an cika ka'idodin da ake buƙata.

Sauran darussan da ƙwararrun ma'aikatan CNC suka raba sun haɗa da zabar saurin yankan da ya dace da ciyarwa, yin amfani da kayan aiki masu dacewa don takamaiman kayan aiki, inganta hanyoyin kayan aiki don rage yawan kayan aiki da haɓaka haɓakawa, aiwatar da ƙirar ƙirar da ta dace, da kiyaye yanayin aiki mai tsabta, fahimta da amfani. hanyoyin kayan aiki daban-daban. Nau'in yankan ruwa, kayan aiki na yau da kullun, gyare-gyaren yankan sigogi bisa ga kaddarorin kayan aiki, daidaita daidaiton kayan aikin aunawa, da koyo da haɓaka ilimin fasaha na injin injin CNC.

Gabaɗaya, waɗannan darussa masu mahimmanci goma sha biyu suna ba da jagora don cimma ingantacciyar mashin ɗin CNC mai inganci. Ta hanyar aiwatar da waɗannan dabarun, ƙwararrun ƙwararrun mashinan CNC na novice na iya haɓaka ƙwarewar su, haɓaka matakai, da ba da sakamako mafi girma.